Among the variety of modern materials their place in the market of building insulation took penopolietilena (PIR), which is used in sandwich panels and insulating the plates with a soft wall. Like any building material, it has several properties characterizing its resistance to fire. And, although our time in the selection of material, this criterion is not in first place, it depends on him the most precious thing — the lives and health of people.

Therefore I propose to evaluate this material from the point of view of fire safety, for clarity, a comparative assessment with other types of insulation. For comparison, take the traditional polyurethane foam (PUR), polystyrene foam (VPPS), extruded polystyrene (EPPS) and stone wool (KV). Also let’s look at the wood. Although she is not a heater, but in a single-layer walls of wooden houses performs a heat insulating function.

Characteristics of fire risk of materials

Fire hazard of building materials is determined by the fire-technical characteristics: combustibility, Flammability, smoke-forming ability and toxicity of combustion products.

All these indicators are important for assessing material properties, but the primary criterion is the Flammability, combustibility because it largely determines the level of other fire-technical indices.

Flammability is the ability of a material to burning. At the same time self-combustion of the material, the degree of damage along the length, the mass loss and temperature rise in a furnace. The results of the test material is assigned a Flammability group from G1 (combustible) to G4 (zelenogorye).

Flammability is the ability of a material to ignition. Building materials by Flammability are divided into 3 groups: B1 (inflammable) to B3 (highly flammable).

Smoke-forming ability characterizes the quantity of smoke emitted by the smoldering material, which in practice means the ability for visual orientation during a fire evacuation. According to this indicator, the materials are divided into 3 groups: D1 (low smoke) to D3 (with high smoke-forming ability).

Toxicity of combustion products providing 4 groups of materials: T1 (low risk) to T4 (chrezvychaynaya).

Everything is relative..

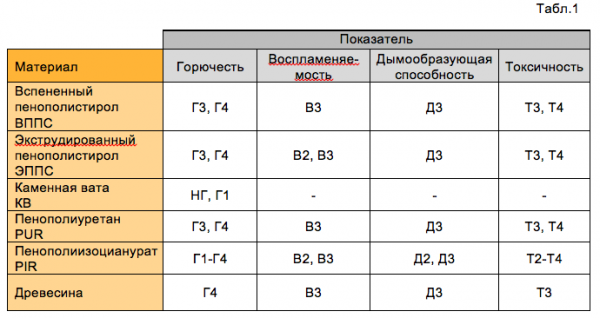

Values of selected materials are taken according to the recommendation of the leading Institute in the field of fire hazard of construction materials, and fire prevention are summarized in table 1.

Foam and extruded polystyrene. The main difference from other types of polymeric insulation is that they are thermoplastics — materials which when exposed to fire, easily melt. In accordance with the requirements of the Federal law № 123 “Technical regulations on fire safety requirements”, if the test material is burning with droplets of the melt — it will automatically belong to the group of combustibility G3, when the melt drops burn something to the Flammability group G4.

Stone wool. The parameter Flammability, it is classified as non-combustible materials in the test the following conditions are true:

- increase the furnace temperature is not more than 50°C;

- the mass loss of the sample not more than 50%;

- the duration of stable flame burning no more than 10sec.

When these conditions are met, the confirmation of other indicators are required.

It should be noted that if the wool is laminated (glued) a layer of foil or foil with polyethylene, this material is combustible and has a group of Flammability G1.

In addition, according to the results of recent studies, properties of insulation materials (which include mineral wool) with breathable structure and an organic binder, in the light of existing standards and regulations are overrated. In particular, certain brands, which are non-combustible materials, can hidden spread burning.

Wood. The material, which is rightfully considered eco-friendly due to its natural origin, it turns out, is not so “green” properties of fire safety. Flammability of wood — the highest G4, if removal of the source flame, the wood continues to burn for a very long time.

The polyurethane foam. PUR is similar to the polystyrene level of fire safety. But the key difference from polystyrene is that it belongs to the class of thermosets — materials that are not able to melt when exposed to elevated temperature, including during combustion.

Penopolistirola. PIR is also a thermoset, which distinguishes it from VPPS and EPPS. But, unlike its closest “relative” of polyurethane foam, it has changed the ratio of main raw materials and special additives.

When burning penopolistirola on its surface formed coke layer, which consists of non-combustible substances. They form a kind of protective shield, which protects the inner layers of the polymer from the high temperature and prevent burning. Such a “protection” provides the increase of the furnace temperature is not more than 135°C and also eliminates the self-burning that can be attributed to the test materials from the PIR to the group of Flammability G1 (sandwich panels and wall plates with tinfoil). PIR is different and other good measures of fire safety (see table.1).

It is worth noting that some brands of PIR-plates is the Flammability group G4. For such brands, for example, include plates with facings of plain paper. When testing the surface of a plate completely burns the sample and receives 100% damage length (like normal wood).

The fire resistance of structures using polyurethane foams

Regulation of building constructions — walls, ceilings, roofs — is the class of fire hazard and fire resistance.

Fire hazard class of structures allows to estimate the degree of its participation in the spread of fire (class K0 — design as a result of fire impact has minimal damage, a class K3 — the lowest, the degree of damage to structures is not specified).

Fire resistance describes the resistance of structures to fire. It is measured in minutes since the beginning of fire exposure before the occurrence of one (or more) signs limit state:

- the loss of bearing capacity ( R );

- the emergence of cross-cutting fractures (E);

- loss of insulating ability (I).

Which buildings are allowed to use designs of a particular class of fire danger and fire resistance, depends on the functional purpose of the building and its dimensions.

Thus, in the low-rise housing construction for height of houses to two floors inclusive of the requirements for the degree of fire resistance and a class of constructive fire danger is not imposed, and height of three storeys they must comply with the requirements of the construction of buildings of III degree of fire resistance. This means that PIR insulation can be used in walls with a fire resistance of R 45, pitched roof with fire resistance RE 15, attic floor with the limit of fire resistance REI 45 and other structures.

Fire safety requirements for commercial and public buildings having large dimensions and functional purpose, which involves a large number of people in the building, or dangerous processes, is significantly higher. But here, the performance of structures with PIR sufficiently large.

So, the degree of fire hazard of sandwich panels with PIR — K1(15), in contrast to the sandwich panel with polystyrene foam (where the rate does not rise above K3). And the degree of fire hazard of the roof with profiled decking and insulation plates PIR is even higher — K0(15).

As a consequence, enclosing and supporting structures with PIR can be used in buildings with a class of constructive fire danger C1-C3 with II-V degree of fire resistance. It should be noted that under these requirements gets 70% of all buildings in the country.

An integrated approach is the basis for the choice

On the one hand, non-combustible materials eliminate the possibility of fire. On the other hand, almost everything in a modern house — furniture, clothes, household items made of flammable materials.

To ensure the house was safe, should comply with fire safety measures — make the walls and ceilings of non-combustible materials such as drywall, lay wiring and install the outlet in a non-combustible decorative layer, to perform processing of wood flame retardant, etc.

As for insulation, its selection should be performed, guided by and other, very important criteria. This strength and thermal performance, durability, technological effectiveness and especially environmental safety under normal operating conditions. Because indirectly they also affect the properties of fire. For example, if the insulation in the construction will eventually subside and homogeneity of this layer in the design will change, you will change the fire safety of this design.

Penopolistirola PIR has a number of advantages on the above criteria both in relation to mineral insulation, and other types of polymer insulation. It has high mechanical strength, ensuring uniformity of the layer, and proven European experience of operating durability. Therefore, the correct solution approach to the choice of insulation will be a balanced approach, which should be used where the criterion of fire safety is not the only one.

Author Ilya Humalin.

The article is based on material provided by the Association NAPPAN.